Category

- Products

-

- Contact us

Home » Soft Starters Knowledge » Soft Starter Torque Control System

Soft Starter Torque Control System

There are several methods available to soft start a motor. The more traditional methods are Direct-on-line, Star/Delta, Auto transformer and Primary resistance starters. The more sophisticated methods also provide a soft stop and include Soft Starters and Variable Frequency Drives. Variable frequency drives can provide a better soft start with significantly lower starting currents and many other benefits including energy savings. However, a Soft Starter may provide a more economical solution to motor starting over the life of the motor.

Gozuk soft starter is a Torque Control System developed to overcome this problem with greater control over the acceleration torque in the motor. The torque is controlled in a manner which suits the type of load to achieve a linear acceleration in motor shaft speed. This control system is also active during the deceleration phase, providing a soft stop where the motor decelerates at a constant rate. This can be used to overcome water hammer problems associated with the closing or slamming of check valves.

Gozuk Soft Starter System Key Benefits:

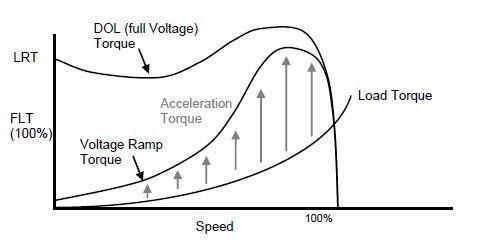

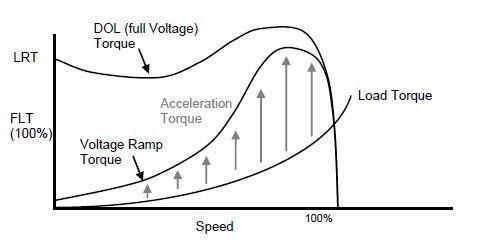

Since the torque required by the load may not be linear, the torque delivered by the soft starter must match that of the load. To achieve this, the torque developed in the motor must be the sum of the 'acceleration torque' and the load torque at a specific speed.

Below illustrates the constant acceleration torque applied for different load types:

1) Constant Torque type Load (eg. Conveyor)

2) Variable Torque type Load (eg. Pump/Fan)

How is this achieved?

The soft starter continually monitors start variables such as motor current, voltage and power factor to determine the input electrical power. From the motor parameters, the IR & magnetic losses are used to calculate the Air Gap Power (ie. the power transmitted to the motor shaft). With an instantaneous value of shaft power the instantaneous torque can be determined. With this information we can vary the thyristor conduction to achieve the desired torque. The torque is varied to follow a specific curve, based on the initial torque setting, the final torque setting and the profile selected. The end result is equal acceleration torque over the ramp period to provide a linear acceleration in motor shaft speed. The profile is user adjustable allowing for non-linear torques if required to other or unusual types of loads.

Summary

The Soft Starter Torque Control System provides smoother starting & stopping, allowing ramp profiling to produce a linear acceleration and deceleration of the motor speed. There are many benefits with variable torque loads such a pumps. A linear acceleration and deceleration provides better control to eliminate water hammer problems. The soft starter combines this superior torque control system with a robust design to suit all types of loads and applications. All models include substantial heatsink mass with temperature controlled force ventilation to accommodate the more severe (heavy) duty applications.

Soft Starters provide the following basic benefits:

- Reduced stresses and wear on the mechanics of the system

- Reduced starting currents

- Minimize voltage dips on the supply

- Lowered Peak demand charges

- Eliminate belt slippage on fans

- Smooth acceleration of motor / load

Gozuk soft starter is a Torque Control System developed to overcome this problem with greater control over the acceleration torque in the motor. The torque is controlled in a manner which suits the type of load to achieve a linear acceleration in motor shaft speed. This control system is also active during the deceleration phase, providing a soft stop where the motor decelerates at a constant rate. This can be used to overcome water hammer problems associated with the closing or slamming of check valves.

Gozuk Soft Starter System Key Benefits:

- A true linear acceleration of the load and motor for variable & constant torque loads.

- Reduced stresses and wear on the mechanics of the system.

- Ramp profiling to better match type of load such as variable torque loads. Better control of pumps and fans.

- Torque Control available in Accelerate & Decelerate Modes and 3wire or 6 wire motor configuration.

- Eliminate water hammer problems.

- Reduced peak current draw, especially at motor pull-in/pull-out operating points.

- Reduced heating in motor at low speeds.

- No instability due to changing power factor. Closed loop system to monitor and react to changing power factor.

- No instability due to slot ripple in 3 wire and 6 wire operation.

- Better control of deceleration through closed loop torque control system.

- No external speed sensor required to produce superior performance.

Since the torque required by the load may not be linear, the torque delivered by the soft starter must match that of the load. To achieve this, the torque developed in the motor must be the sum of the 'acceleration torque' and the load torque at a specific speed.

Below illustrates the constant acceleration torque applied for different load types:

1) Constant Torque type Load (eg. Conveyor)

2) Variable Torque type Load (eg. Pump/Fan)

How is this achieved?

The soft starter continually monitors start variables such as motor current, voltage and power factor to determine the input electrical power. From the motor parameters, the IR & magnetic losses are used to calculate the Air Gap Power (ie. the power transmitted to the motor shaft). With an instantaneous value of shaft power the instantaneous torque can be determined. With this information we can vary the thyristor conduction to achieve the desired torque. The torque is varied to follow a specific curve, based on the initial torque setting, the final torque setting and the profile selected. The end result is equal acceleration torque over the ramp period to provide a linear acceleration in motor shaft speed. The profile is user adjustable allowing for non-linear torques if required to other or unusual types of loads.

Summary

The Soft Starter Torque Control System provides smoother starting & stopping, allowing ramp profiling to produce a linear acceleration and deceleration of the motor speed. There are many benefits with variable torque loads such a pumps. A linear acceleration and deceleration provides better control to eliminate water hammer problems. The soft starter combines this superior torque control system with a robust design to suit all types of loads and applications. All models include substantial heatsink mass with temperature controlled force ventilation to accommodate the more severe (heavy) duty applications.

Post a Comment:

You may also like: