Category

- Products

-

- Contact us

Home » Soft Starters Knowledge » How does soft start work?

How does soft start work?

A soft starter is any device which controls the acceleration of an electric motor by means of controlling the applied voltage.

An Induction motor has the ability to self start owing to the interaction between the rotating magnetic field flux and the rotor winding flux, causing a high rotor current as torque is increased. As a result the stator draws high current and by the time the motor reaches to full speed, a large amount of current (greater than the rated current) is drawn and this can cause heating up of the motor, eventually damaging it. To prevent this, motor starters are needed.

Motor starting can be in 3 ways:

In technical terms, a soft starter is any device which reduces the torque applied to the electric motor. It generally consists of solid state devices like thyristors to control the application of supply voltage to the motor. The starter works on the fact that the torque is proportional to the square of the starting current, which in turn is proportional to the applied voltage. Thus the torque and the current can be adjusted by reducing the voltage at the time of starting the motor.

There can be two types of control using soft starter:

1) Open Control: A start voltage is applied with time, irrespective of the current drawn or the speed of the motor. For each phase two SCRs are connected back to back and the SCRs are conducted initially at a delay of 180 degrees during the respective half wave cycles (for which each SCR conducts). This delay is reduced gradually with time until the applied voltage ramps up to the full supply voltage. This is also known as Time Voltage Ramp System. This method is not relevant as it doesn’t actually control the motor acceleration.

2) Closed Loop Control: Any of the motor output characteristics like the current drawn or the speed is monitored and the starting voltage is modified accordingly to get the required response. The current in each phase is monitored and if it exceeds a certain set point, the time voltage ramp is halted.

Thus basic principle of soft starter is by controlling the conduction angle of the SCRs the application of supply voltage can be controlled.

Components of a basic soft starter

Working Example of Electronic Soft Start System for 3 phase induction motor

The system consists of the following components:

The level voltage is generated using the comparator LM324 whose inverting terminal is fed using a fixed voltage source and the non inverting terminal is fed through a capacitor connected to the collector of an NPN transistor. The charging and discharging of the capacitor causes the output of the comparator to change accordingly and the voltage level to change from high to low. This output level voltage is applied to the non inverting terminal of another comparator LM339 whose inverting terminal is fed using a ramp voltage. This ramp voltage is produced using another comparator LM339 which compares the pulsating DC voltage applied at its inverting terminal to the pure DC voltage at its non inverting terminal and generates a zero voltage reference signal which is converted to a ramp signal by the charging and discharging of a electrolyte capacitor.

The 3rd comparator LM339 produces a High pulse width signal for every high level voltage, which decreases gradually as the level voltage reduces. This signal is inverted and applied to the Opto isolator, which provides gate pulses to the SCRs. As voltage level falls, the pulse width of the Opto isolator increases and more the pulse width, lesser is the delay and gradually the SCR is triggered without any delay. Thus by controlling the duration between the pulses or delay between applications of pulses, the firing angle of SCR is controlled and the application of supply current is controlled, thus controlling the motor output torque.

The whole process is actually an open loop control system where the time of application of gate triggering pulses to each SCR is controlled based on the how earlier the ramp voltage decreases from the level voltage.

Now that we have learnt about how an electronic soft start system works, let us recollect few reasons why it is preferred over other methods.

An Induction motor has the ability to self start owing to the interaction between the rotating magnetic field flux and the rotor winding flux, causing a high rotor current as torque is increased. As a result the stator draws high current and by the time the motor reaches to full speed, a large amount of current (greater than the rated current) is drawn and this can cause heating up of the motor, eventually damaging it. To prevent this, motor starters are needed.

Motor starting can be in 3 ways:

- Applying full load voltage at intervals of time: Direct On Line Starting

- Applying reduced voltage gradually: Star Delta Starter and Soft starter

- Applying part winding starting: Autotransformer starter

Soft Start Definition

In technical terms, a soft starter is any device which reduces the torque applied to the electric motor. It generally consists of solid state devices like thyristors to control the application of supply voltage to the motor. The starter works on the fact that the torque is proportional to the square of the starting current, which in turn is proportional to the applied voltage. Thus the torque and the current can be adjusted by reducing the voltage at the time of starting the motor.

There can be two types of control using soft starter:

1) Open Control: A start voltage is applied with time, irrespective of the current drawn or the speed of the motor. For each phase two SCRs are connected back to back and the SCRs are conducted initially at a delay of 180 degrees during the respective half wave cycles (for which each SCR conducts). This delay is reduced gradually with time until the applied voltage ramps up to the full supply voltage. This is also known as Time Voltage Ramp System. This method is not relevant as it doesn’t actually control the motor acceleration.

2) Closed Loop Control: Any of the motor output characteristics like the current drawn or the speed is monitored and the starting voltage is modified accordingly to get the required response. The current in each phase is monitored and if it exceeds a certain set point, the time voltage ramp is halted.

Thus basic principle of soft starter is by controlling the conduction angle of the SCRs the application of supply voltage can be controlled.

Components of a basic soft starter

- Power switches like SCRs which need to be phase controlled such that they are applied for each part of the cycle. For a 3 phase motor, two SCRs are connected back to back for each phase. The switching devices need to be rated at least three times more than the line voltage.

- Control Logic using PID controllers or Microcontrollers or any other logic to control the application of gate voltage to the SCR, i.e. to control the firing angle of SCRs in order to make the SCR conduct at the required part of the supply voltage cycle.

Working Example of Electronic Soft Start System for 3 phase induction motor

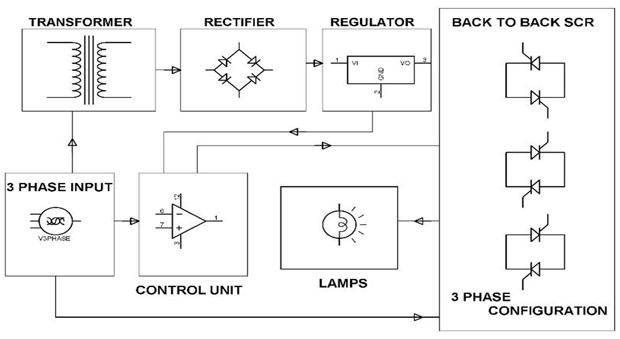

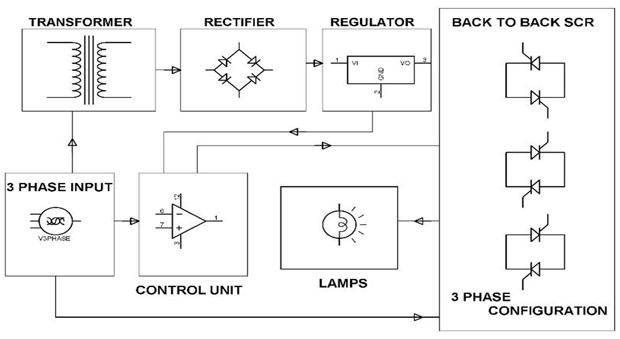

The system consists of the following components:

- Two back to back SCRs for each phase, i.e. 6 SCRs in total.

- Control Logic circuitry in form of two comparators- LM324 and LM339 to produce the level and the ramp voltage and an opto-isolator to control the application of gate voltage to the each SCR in each phase.

The level voltage is generated using the comparator LM324 whose inverting terminal is fed using a fixed voltage source and the non inverting terminal is fed through a capacitor connected to the collector of an NPN transistor. The charging and discharging of the capacitor causes the output of the comparator to change accordingly and the voltage level to change from high to low. This output level voltage is applied to the non inverting terminal of another comparator LM339 whose inverting terminal is fed using a ramp voltage. This ramp voltage is produced using another comparator LM339 which compares the pulsating DC voltage applied at its inverting terminal to the pure DC voltage at its non inverting terminal and generates a zero voltage reference signal which is converted to a ramp signal by the charging and discharging of a electrolyte capacitor.

The 3rd comparator LM339 produces a High pulse width signal for every high level voltage, which decreases gradually as the level voltage reduces. This signal is inverted and applied to the Opto isolator, which provides gate pulses to the SCRs. As voltage level falls, the pulse width of the Opto isolator increases and more the pulse width, lesser is the delay and gradually the SCR is triggered without any delay. Thus by controlling the duration between the pulses or delay between applications of pulses, the firing angle of SCR is controlled and the application of supply current is controlled, thus controlling the motor output torque.

The whole process is actually an open loop control system where the time of application of gate triggering pulses to each SCR is controlled based on the how earlier the ramp voltage decreases from the level voltage.

Advantages of Soft Start

Now that we have learnt about how an electronic soft start system works, let us recollect few reasons why it is preferred over other methods.

- Improved Efficiency: The efficiency of soft starter system using solid state switches is more owing to the low on state voltage.

- Controlled startup: The starting current can be controlled smoothly by easily altering the starting voltage and this ensures smooth starting of the motor without any jerks.

- Controlled acceleration: Motor acceleration is controlled smoothly.

- Low Cost and size: This is ensured with the use of solid state switches.

The problem with the soft starter is the companies that make the soft starter hoarding the parts, when the soft starter fails the company wants the customer to send the whole soft starter in for repairs vice allowing the customer to rebuild on site..if you have 30 soft starters in a particular building or a ship per say in 1-2 years all of those soft starters should need to go back to the company just to replace an SCR, how about building a better soft starter that could possibly last 4-6 years or allow the customer to make repairs on site.The loud clunk coming from the soft starter is present in over 60% of the soft starter upon motor start up.

Nice Explanation

Post a Comment:

You may also like: